At AboutMechanics, we're committed to delivering accurate, trustworthy information. Our expert-authored content is rigorously fact-checked and sourced from credible authorities. Discover how we uphold the highest standards in providing you with reliable knowledge.

What Is an Actuator Positioner?

An actuator positioner is a system interface that uses system inputs to adjust an actuator through a variable range of positions according to real-time system requirements. Essentially a servo system, the actuator positioner uses inputs from system sensors that supply information regarding the actuator's present position. This information is compared by the positioner to a pre-programmed ideal scenario or other system inputs. If any disparity exists between the two sets of information, the positioner adjusts the actuator accordingly to correct the difference. Actuator positioners are used in a wide variety of applications, such as machine tool parts, naval gun turrets, guidance systems and flow control valves.

Actuators are devices that supply remote work by applying movement to a secondary device where it is impractical or dangerous for a human operator to intervene. In many cases, this movement is a simple linear or rotary motion of a repetitive and finite nature. There are, however, many applications where an actuator is required to produce a variety of positional changes within the limits of its operational range in response to system or environmental demands. A naval gun turret is a good example of this type of operational situation. The actuators that rotate the turret and elevate and depress the gun barrels are constantly required to change their position in relation to the position and range of a potential target.

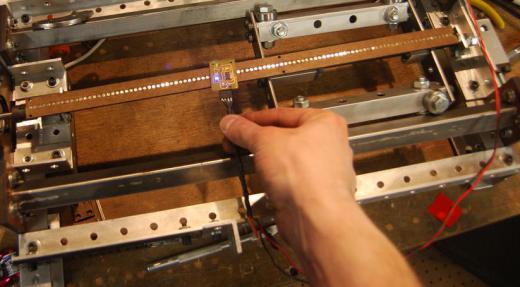

To achieve this type of fine control, an actuator positioner system is used. This type of actuator system consists of a full-range actuator, a controller and an interface unit. The interface unit collects system inputs and operator commands or contains a set of pre-programmed data. It also collects sensor inputs that give a real-time indication of the actuator's exact position.

The system inputs, operator commands or program data represent an ideal or desired situation. The interface then compares this ideal situation to the actuator's positional information. If a difference is detected between these two sets of information, an error state is declared by the interface. It then instructs the controller to move the actuator — and consequently the system component in question — to correct the error state. After the error state has been canceled, the actuator positioner will stop the actuator, thereby restoring the desired parameters.

AS FEATURED ON:

AS FEATURED ON:

Discuss this Article

Post your comments