At EasyTechJunkie, we're committed to delivering accurate, trustworthy information. Our expert-authored content is rigorously fact-checked and sourced from credible authorities. Discover how we uphold the highest standards in providing you with reliable knowledge.

What Are Intrinsic Semiconductors?

Intrinsic semiconductors are a pure form of elements that usually have four valence electrons. A special process can be done to make intrinsic semiconductors into negative (N)-type or positive (P)-type semiconductors. The uses of P-type and N-type semiconductors include bipolar junction transistors (BJT), field-effect transistors (FET), and silicon-controlled rectifiers (SCR).

Good conductors of electricity, such as copper, easily lose electrons to other atoms inside the material, while semiconductors are partially conducting and partially insulating. Both silicon and germanium are four-valence elements. Silicon is a common material for semiconductors, although germanium is also used for high-frequency applications. The difference between silicon and germanium is that the forward voltage drop in germanium is about 0.2 volt (V), compared to 0.7 V in silicon.

When making intrinsic semiconductors, silicon is melted at a very high temperature in an inert gas or a vacuum. The resulting molten material looks very much like a molten glass. Through a process called growing, a spinning grower slowly pulls the molten silicon into an intrinsic material of silicon in the form of a rod about a few inches in diameter.

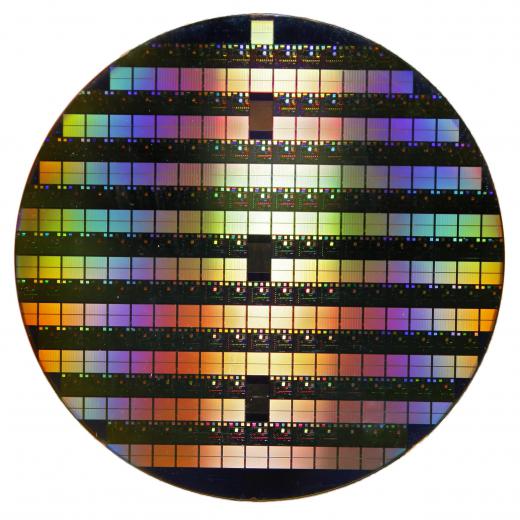

Intrinsic silicon materials, called undoped semiconductors, intrinsic (i)-type semiconductors, or intrinsic semiconductors, are of little use to the electronics industry. The useful form of silicon is a result of adding special elements, known as dopants, in a process called doping, wherein dopants, such as phosphorus or boron, are added while the silicon is still molten. When phosphorus is added to silicon, an extra electron makes the silicon an N-type semiconductor. The next step after an N-type rod of silicon has been grown is slicing, wherein the glass-like, rod-shaped material will be sliced to produce thin silicon wafers. Special techniques, such as the surface acoustic wave (SAW), are used in slicing a very hard material, such as phosphorus-doped silicon.

The silicon wafers generated by slicing may be scribed on the x-axis and then on the y-axis, resulting in a huge quantity of N-type semiconductors. Later, P-type semiconductors are also produced and made ready for the assembly process. At this point, the intrinsic semiconductors have been transformed into extrinsic semiconductors. The simplest assembly of an N-type and a P-type semiconductor is a positive-negative (P-N) junction known as a diode, which is like a one-way valve. The P-N junction that was generated by the contact of the N-type and P-type semiconductor now has a special characteristic known as a one-way conductivity.

AS FEATURED ON:

AS FEATURED ON:

Discuss this Article

Post your comments